GoodMills Innovation expands plant-based protein capabilities with new Hamburg facility

Hamburg-based ingredient specialist GoodMills Innovation has unveiled a state-of-the-art production facility, signalling a significant expansion of its plant-based protein processing capabilities. The multi-million-euro investment underscores the company’s commitment to driving innovation in the burgeoning market for meat and fish alternatives.

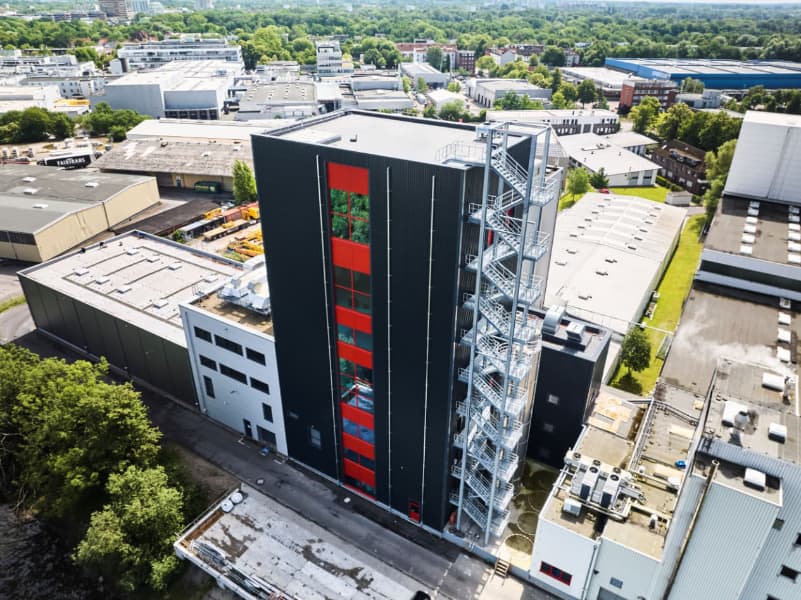

GoodMills Innovation Tower III

GoodMills Innovation has officially opened its newest production facility, dubbed “Tower III”, at its Hamburg site. The 42-metre-tall structure, visible from afar, houses 2,500 square metres of production space spread across seven levels. This expansion marks a pivotal moment for the company as it seeks to establish itself as an international centre of excellence for plant protein texturization.

The new facility incorporates a fully automated production process that combines extrusion, texturization, wet defibring, and hydrothermal product refinement. This integrated approach allows GoodMills Innovation to significantly expand its portfolio of plant-based ingredients, particularly those aimed at the meat and fish alternative sectors.

Katharina Haack, Head of Marketing Communications at GoodMills Innovation, emphasised the strategic importance of the investment: “Plant-based nutrition is a building block towards a more sustainable future. And this is where we want to make a major contribution. Our raw materials enable manufacturers to produce high-quality meat and fish alternatives on an industrial scale, all of which are convincing in terms of taste, sensory properties and nutritional physiology.”

Technological advancements

The new tower represents a significant technological leap for GoodMills Innovation. By integrating multiple processing steps into a single, automated production line, the company aims to achieve greater efficiency and consistency in its plant protein texturization processes.

Food scientists will be particularly interested in the combination of extrusion and wet defibring technologies. This pairing allows for the creation of a wider range of textures and functionalities in plant-based proteins, potentially opening up new applications in food product development.

The hydrothermal refinement capabilities of the new facility also merit attention. This process can enhance the nutritional profile and sensory characteristics of plant proteins, addressing some of the persistent challenges in creating convincing meat and fish analogues.

Sustainability focus

Beyond its technological capabilities, Tower III has been designed with sustainability at its core. The construction project adhered to comprehensive sustainability requirements, encompassing energy concepts, building materials, and the selection of project partners.

Notably, the facility operates entirely without fossil fuels, instead utilising particularly energy-efficient machinery, equipment, and processes. GoodMills Innovation projects that these measures will result in energy savings of up to 40 per cent compared to conventional technology.

This focus on sustainability extends beyond the facility itself. The tower’s central location on a navigable branch of the Elbe River provides GoodMills Innovation with direct access to grinding and specialty mill products from the Group’s sister company, Aurora Mühle Hamburg, as well as seaport access. This strategic positioning could potentially reduce transportation-related emissions in the company’s supply chain.

GoodMills Innovation VITATEX Wheat Flakes

Market implications

The commissioning of Tower III positions GoodMills Innovation to meet the growing demand for sustainable and nutritionally optimised plant-based texturates. This expansion of production capacity comes at a crucial time, as consumer interest in plant-based alternatives continues to rise globally.

For food scientists and product developers, the increased availability of sophisticated plant protein ingredients could accelerate innovation in the alternative protein space. GoodMills Innovation’s focus on clean label ingredients based on cereals and pulses aligns with current market trends towards simple, recognisable ingredient lists.

Furthermore, the company’s emphasis on combining sensory appeal with nutritional benefits – such as selected dietary fibres and improved Nutri-Scores – speaks to the ongoing challenge of creating plant-based products that satisfy both taste and health requirements.

Looking ahead

As GoodMills Innovation brings its expanded capabilities online, the food science community will be watching closely to see how this investment translates into new ingredient solutions. The company’s position within the GoodMills Group, Europe’s largest milling group, suggests that it has the resources and supply chain integration to potentially make a significant impact on the plant-based ingredient market.

Katharina Haack commented: “With this investment, we can meet the growing demand for sustainable and healthy plant-based texturates and play a key role in shaping the development of plant-based nutrition on a global scale.”

As the alternative protein sector continues to evolve rapidly, facilities like Tower III may prove crucial in bridging the gap between consumer expectations and technical feasibility in plant-based products. Food scientists and product developers will undoubtedly be keen to explore the new possibilities that GoodMills Innovation’s expanded capabilities may offer.