PPM technologies launches automated coating system for confectionery applications

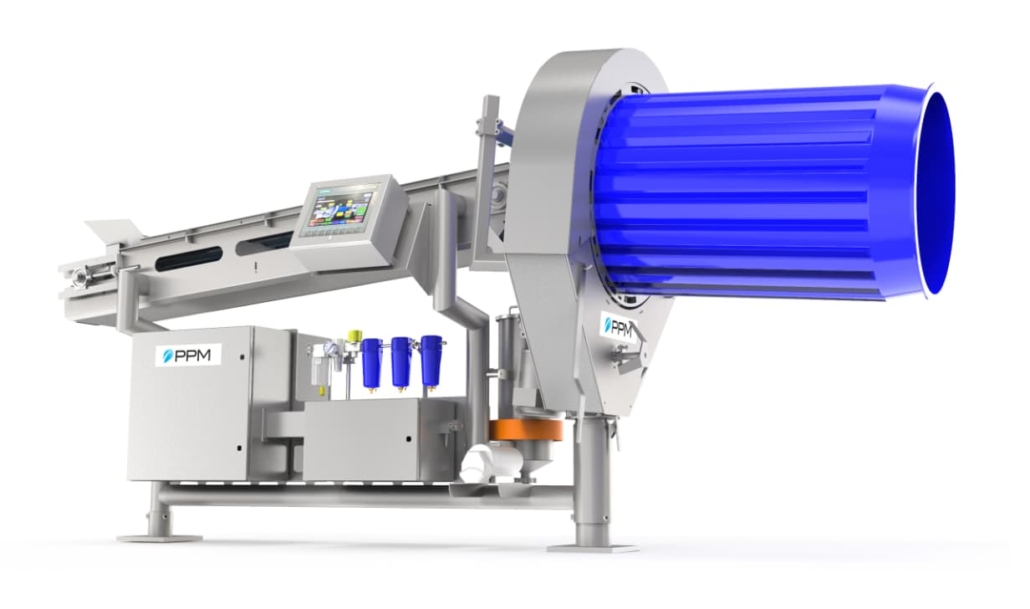

PPM Technologies has introduced the FlavorWright SmartSpray™, a continuous coating system specifically engineered for confectionery products including vitamins and gummies. The system, which integrates belt conveying, liquid application and tumbling technologies, offers automated control of coating operations through a unified interface.

Technical specifications

The system’s architecture comprises three primary components: a specialised belt conveyor designed for handling challenging confectionery products, a precision liquid applicator, and a tumbling drum. The liquid applicator generates controlled spray patterns to prevent oversaturation whilst ensuring uniform coverage. The subsequent tumbling action facilitates even distribution across product surfaces.

The system’s process control capabilities allow manufacturers to adjust both conveyor speed and drum angle, enabling optimisation of product dwell time based on specific product characteristics. Operation is managed through a recipe-driven touchscreen human-machine interface (HMI), which facilitates consistent, repeatable results and tool-free changeovers.

Modular design features

The equipment’s modular construction incorporates interchangeable components to accommodate varying production requirements. Two drum options are available, manufactured from either food-grade plastic or stainless steel. The plastic variants feature seamless, FDA-approved construction with non-stick properties to minimise product accumulation. These drums utilise a magnetic quick-change system for efficient replacement.

“We designed SmartSpray with a specialised belt conveyor for wet, sticky and hard-to-move confectionery products to ensure effective yet gentle handling while achieving accurate and reliable coating coverage”, explained Jack Lee, Duravant Group President – Food Sorting and Handling Solutions.

Sanitation considerations

The system’s hygiene-focused design incorporates NEMA 4X-rated components suitable for washdown environments, complemented by food-grade stainless steel construction throughout. Its compact configuration facilitates integration into existing production lines, typically positioned between depositing and packaging operations.

Production efficiency

When compared with manual batch coating methods, the automated continuous process delivers enhanced throughput whilst reducing labour requirements and coating material waste. The system can be integrated with downstream dry seasoning equipment to create a comprehensive coating solution managed through a single control interface.

The engineering approach prioritises operational efficiency through:

- Automated recipe management

- Tool-free changeover capability

- Precise control of processing parameters

- Optimised product handling for challenging materials

- Integrated washdown protection

- Modular component design

- For more information, visit: ppmtech.com