Refining omega-3 oils for quality, purity and taste

Omega-3 fatty acids have several positive effects on the immune system. With more and more consumers seeking an alternative to fish, high-quality vegetable- and microalgae-derived oils are becoming increasingly popular. Nutriswiss, the Swiss market leader in the field of refining specialty and organic edible oils, has established gentle processes that deliver superior-quality oils with a sufficiently high omega-3 fat content for food applications and supplements.

In the context of the coronavirus pandemic, many people are now paying more attention to the fragility of their own health and looking to strengthen their immune system. The ongoing quest for an effective therapy against the virus is, at the same time, driving further research into the benefits of omega-3 fatty acids. As our body is unable to produce them by itself, they must be absorbed through food. For a long time, fatty fish and seafood such as mussels were said to be the most important sources of omega-3. But not every consumer likes the inherent fishy taste; as such, perfecting the sensory profile is a significant challenge. Similarly, it’s critical to meet certain quality and stability requirements in order for the end product to be considered safe.

This is where Nutriswiss comes into play. The refinery specialises in purifying and modifying high-quality edible oils for both domestic and international markets.

Michel Burla, CEO of Nutriswiss, says: “The immune health segment offers great potential, particularly in the area of omega-3 products. Before the pandemic, omega-3 was in demand as an ingredient with a recognised effect on the immune system, especially in infant formulas; now, however, there is growing demand for similarly enriched functional foods for adults.”

Why omega-3 fatty acids are a key ingredient

It is known that omega-3 fatty acids activate immune cells such as neutrophil granulocytes, macrophages and killer cells. [1] Furthermore, mediator molecules such as prostaglandins are also triggered and subsequently bring the immune system into a state of greater readiness. Additionally, long-chain omega-3 fatty acids play an important role in blood pressure regulation, kidney function, healthy eyes, brain growth and development, particularly during the first two years of life, as well as in numerous inflammatory and immunological reactions. In December 2020, a scientific review paper was published that discussed the possible antiviral effect of supplementation with the polyunsaturated fatty acids EPA and DHA against COVID-19. [1] It was suggested that omega-3 helps to maintain the functionality of cell mem- branes, activates immune cells and plays an important part in the inflammatory processes of immune defence. These essential fatty acids also inhibit viral replication by inducing the production of interferon.[2] The results show that omega-3 has a positive impact in a variety of areas, including strengthening the immune system.

Safe and taste-neutral

It should be noted that omega-3 oils oxidise quickly and, like any other crude oil, can be contaminated during cultivation, transport or processing. However, such contaminants are not the only sub- stances that must be eliminated from a crude oil during refining. Due to their apolar structure, lipids are highly susceptible to environmental contaminants too. Furthermore, in vegetable oils such as linseed oil, insecticides, fungicides and herbicides used in traditional farming must be removed. Additionally, saturated mineral oil hydrocarbons (MOSH) and aromatic mineral oil hydro- carbons (MOAH) originating from exhaust gases or emissions from industrial plants, among other sources, may have been trans- ferred to the product in the course of processing and packaging. That’s why Nutriswiss adheres to a policy of controlled sourcing and has recently established particularly effective processes using innovative and gentle refining methods.

Purifying processes that work well for other vegetable oils operate at temperatures of 180–250°C. However, this would be an excessive thermal load for omega-3 oils. Nutriswiss has therefore established a gentle and effective process that subjects the raw materials to minimal thermal stress. As a company that specialises in refining superior, high-purity oils, their core competence is preserving the important micronutrients and, simultaneously, eradicating harmful substances. “To meet the highest quality values, we are constantly investing in complementary technologies,” explains Burla. Nutriswiss developed a physical distillation technology to purify crude oils that maximises the yield and minimises the level of contaminants. By optimising the omega-3 to omega-6 fatty acid ratios, as well as enriching the final product with other micronutrients, Nutriswiss produces blends with completely neutral sensory properties that meet the very specific requirements of EU regulations and customers.

Owing to the short residence time, the thermal load remains low and almost no process contaminants – such as trans fatty acids or chloro fatty acid esters (3-MCPD) – are formed. As soon as the extracted oils are micro-encapsulated or powdered, the valuable fatty acids are completely isolated, which makes further decom- position reactions less likely. Nutriswiss ensures, no matter whether the extract is derived from fish or algae or plants, that the final product is organoleptically neutral.

Diminishing oxidation and enhancing purity

When oils containing polyunsaturated fatty acids are exposed to oxygen in the ambient air, an oxidation reaction takes place that triggers decomposition. The consequences of this are off-notes, an unappealing taste (mainly because of the formation of ketones and aldehydes that are responsible for the unpleasant fishy smell) and dark colour. From the outset, Nutriswiss insists on the very best conditions and, therefore, carefully controlled raw material sourcing is essential.

“The best possible outcome is ensured through long-standing collab- orations with suppliers, as well as careful handling of the product in food-grade containers, which protect the raw ingredients from contact with foreign materials and ambient oxygen,” Burla stresses.

Furthermore, before production, each process and method is tested in the laboratory, so that all procedures can be adapted to suit individual applications. To ensure that key data and sensory profile information meet the requirements for pharmaceutical or special nutrition products, the refining steps are carefully planned and monitored. For example, the composition of a baby food formulation, including the optimum ratio of omega-3 and omega-6, can be developed according to specific customer requirements. At the end of the process, even volatile fish oils have a completely neutral taste and odour, and look just like rapeseed oil with a light yellow colouring. The final blends by Nutriswiss, with tailor-made properties, assure the highest levels of quality and purity, and completely neutral sensory characteristics.

Sourcing of fish oil

At Nutriswiss, unprocessed oils of any origin, including fish oil, are purified, i.e. neutralised, bleached, filtered and deodorised, modified and blended. That said, the marine animals from which the fish oil is extracted are at particular risk, as they are in danger of ingesting pesticides that are present in the sea (unlike cultivated algae that grow in containers in a closed system). Although pesticides, such as polychlorinated biphenyls (PCBs), have been officially banned worldwide for several decades, they are nonetheless present in waters around the globe and accumulate in the organisms’ fatty tissues. In fact, a survey in Europe of some biopsied marine animals revealed that PCB levels are exceeding known toxicity thresholds. [3] One further example is dichlorodiphenyltrichloroethane (DDT), which has been prohibited in most industrial countries since the 1970s but is still used as an antimalarial. As a result, the insecticide continues to find its way into our oceans and, therefore, food chain.

For companies whose market positioning demands the highest quality and purity of oils for their formulas, Nutriswiss provides access to a self-developed supply chain. As with oil crops from certificated farming, the Swiss also work with carefully selected partners for marine resources who have pledged to adhere to the highest quality in respect of fishing methods, rearing and transport. Moreover, in the area of fish oil, the elimination of secondary oxidation products succeeds in decreasing the anisidine value below 10, and in some instances below 5, which is equivalent to a premium quality oil.

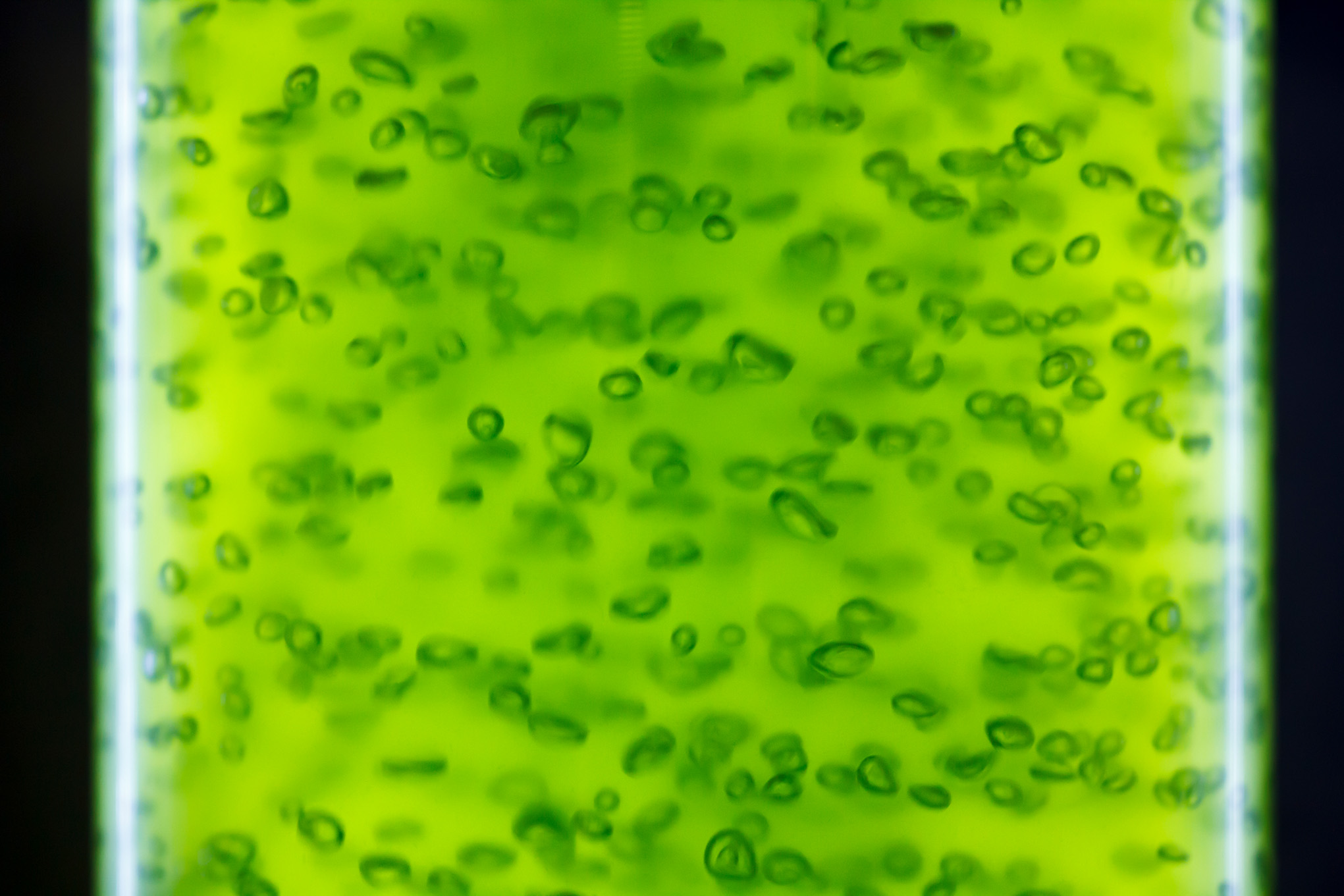

Micro-algae – a sustainable source of omega-3

A number of companies recognise that micro-algae can be a sustainable alternative raw material. As a result, the food industry is increasingly resorting to this rich source of marine omega-3. As they contain up to 50% fat, the refining of the crude oil is challenging, but very efficient and, just as importantly, they provide EPA and even more DHA than tuna oil. Of course, so do fish but they obtain it by consuming algae – hence, algae is a perfect direct source for omega-3. Not only that, but algae farming is more environmentally friendly and helps to protect fish populations. Despite the fact that the microalgae market is still in the exploration phase, processors and refiners like Nutriswiss are ahead of the game and pushing further research and product development with algae oil. While fish oil is still the number one source of omega-3s, algae could well be the resource of the future. At Nutriswiss, years of expertise in processing fish and algae oils equip them to meet the high demands of the market. Whether the extract is derived from fish, algae or plants, the end result is sensory neutrality.

References

- Hathaway D, Pandav K, Patel M, et al. Omega 3 Fatty Acids and COVID-19: A Comprehensive Review. Infect Chemother. 2020;52(4):478-495

- Eslamloo K, Xue X, Hall JR, Smith NC, Caballero-Solares A, Parrish CC, Taylor RG, Rise ML. Transcriptome profiling of antiviral immune and dietary fatty acid dependent responses of Atlantic salmon macrophage-like cells. BMC Genomics. 2017;18:706.

- Jepson, P. D. et al. PCB pollution continues to impact populations of orcas and other dolphins in European waters. Sci. Rep.6, 18573; doi: 10.1038/srep18573 (2016).

Nutriswiss’s distillation process preserves micronutrients and increases the yield of omega-3 fatty acids. CREDIT: Nutriswiss

Microalgae are becoming increasingly important for nutrition since the discovery that they can serve as a important, sustainable source of omega-3 oil with a significant EPA and DHA content. CREDIT: Nutriswiss

Michel Burla,

CEO of Nutriswiss

CREDIT: Nutriswiss

Sensory optimised and highly pure olive oils

Nutriswiss technology enables the gentle refinement of vegetable oils and compliance with current pollution limits

As a result of EU Regulation 2020/1322, new maximum levels for 3-MCPD and glycidol in olive oil and other vegetable oils have been in force since January 2021. Nutriswiss can minimise the presence of these process-related contaminants with the help of a special refining technology.

The Swiss speciality and organic edible oils expert uses a particularly gentle process that refines oils at low temperatures. In this way, oil producers can not only optimise the sensory profile of their products and increase their yield, but also meet the new legal requirements. On 1 January 2021, the European Commission Regulation set limits of 1250 μg of 3-MCPD and 1000 μg of glycidol per kg of edible oil. Even stricter regulations apply to infant and children’s food (15 μg/kg of 3-MCPD and 6.0 μg/kg of glycidol for liquid infant formula).

With a particular focus on refined olive oil, in which high process contaminant values are often seen, Nutriswiss subsequently set new standards for a wide range of products. After refining, labor- atory analyses now show values that are close to the detection limit for both process contaminants and far below legal limits.

Nutriswiss can also refine heavily contaminated oils or those with a high acid value, such as olive pomace or lampante oils, using special processes, so that an organoleptically acceptable, edible and safe food is produced. The olive oil raffinate can then be mixed with virgin olive oils, for example, and marketed as a blend or supplied to the food industry for further processing. Oils that are difficult to refine and would otherwise be unmark- etable now benefit from a new lease of life.

Unlike traditional vegetable oil refining, Nutriswiss doesn’t use timeconsuming or high-temperature processes to remove pesti- cides and mineral oil residues (MOSH/MOAH). Heat promotes the formation of potentially harmful glycidyl fatty acid esters and chlorine-fatty acid esters such as 3-MCPD. Instead, the company relies on physical neutralisation using modern distillation technology and subsequent mild deodorisation. In this way, no process contaminants are formed. At the same time, valuable ingredients are protected, off-flavours are removed and pesticides, MOSH/MOAH, polycyclic hydrocarbons (PAH) and plasticisers such as DEHP are significantly reduced.

Michel Burla, Managing Director of Nutriswiss, said: “Manufacturers of vegetable oils face increasingly stringent legal requirements, such as stricter limits for pollutants. With our state-of-the-art technologies, we can comprehensively meet their needs and support our customers. This applies not only to olive oil, but to a wide range of vegetable and animal oils, such as rapeseed, linseed, fish, algae or hemp oil.”