Researchers develop instant version of trendy ‘Golden Milk’

Researchers at the University of Georgia have developed an efficient method to create an instant, plant-based version of the popular ‘golden milk’ beverage, preserving the beneficial properties of curcumin while extending its shelf life.

Instant Turmeric Latte: A novel approach to curcumin extraction and encapsulation

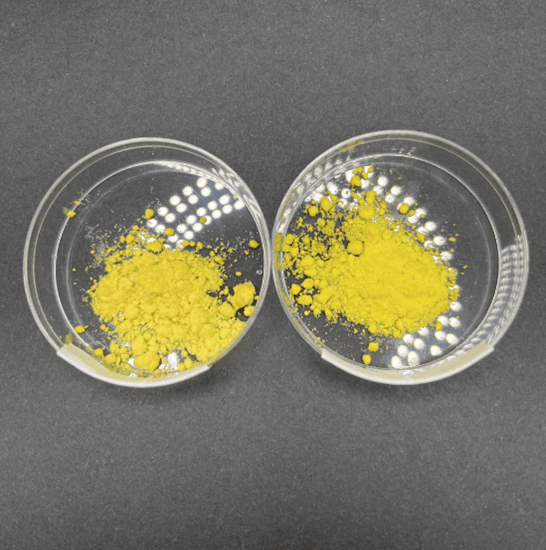

Inspired by golden milk, this powdered golden soy milk made from turmeric (left) or curcumin (right) is easy to produce and has an extended shelf life. Credit: Anthony Suryamiharja

Researchers from the University of Georgia have unveiled a novel technique for extracting and encapsulating curcumin, the bioactive compound found in turmeric, within plant-based milk. This method, presented at the American Chemical Society (ACS) Fall 2024 meeting, offers a promising approach to creating an instant version of the trendy ‘golden milk’ beverage whilst maintaining its potential health benefits.

The challenge of curcumin extraction

Curcumin, a polyphenol found in turmeric, has been the subject of numerous studies investigating its potential anti-inflammatory and antioxidant effects. However, traditional extraction methods for curcumin are often complex, time-consuming, and energy-intensive, typically requiring organic solvents and multiple days of processing.

Moreover, curcumin’s tendency to degrade over time poses challenges for product shelf life. These factors have limited the widespread incorporation of curcumin into food products, despite its potential health benefits.

A pH-driven approach

The research team, led by graduate student Anthony Suryamiharja, developed what they term a ‘post pH-driven’ (PPD) method to simultaneously extract and encapsulate curcumin in plant-based milk. The process begins by adding turmeric powder to an alkaline solution, where the high pH increases curcumin’s solubility, facilitating easier extraction compared to plain water.

This deep red, curcumin-rich solution is then added to soy milk, resulting in a dark yellow mixture. The pH is subsequently neutralised to around 7, making it suitable for consumption. To further preserve the product, the researchers employ freeze-drying to remove water from the solution, yielding an instant golden milk powder.

Encapsulation for improved bioavailability and stability

A key advantage of this method is the encapsulation of curcumin within oil droplets in the soy milk. This encapsulation serves two primary purposes:

- Enhanced bioavailability: When consumed, the body recognises the encapsulated curcumin as fat, potentially increasing its bioavailability.

- Improved stability: Encapsulation protects the curcumin from air and water, preserving it and extending its shelf life.

The researchers report that their method extracts curcumin from turmeric more efficiently than existing techniques. While the study focused on soy milk due to its high amino acid content, the team suggests that the method could be applied to other plant-based milk alternatives, offering options for those with soy allergies.

Furthermore, the pH-driven extraction approach shows promise for application to other plant compounds with similar properties. Hualu Zhou, a member of the research team, noted: “When we use the same method, within around a minute we can extract the polyphenols.” This efficiency could have implications for upcycling by-products and reducing food waste in fruit and vegetable farming.

Future applications and research directions

While further research is needed before this instant golden milk powder becomes commercially available, the initial results are promising. The team hopes their work will help shine a light on the chemistry behind seemingly simple beverages whilst improving their nutritional value and convenience.

Suryamiharja explained the broader implications of their research: “People usually do a lot of simple things in the kitchen, but they don’t really realize there’s a chemistry behind it. So, we’re trying to explain those unspoken things in a simple way.”

The researchers achieved extraction and encapsulation efficiencies of approximately 100% for pure curcumin and 80% for turmeric. The slightly lower efficiency for turmeric is attributed to the fact that only about 80% of its curcumin content was extracted, while the encapsulation efficiency approached 100%.

Environmental considerations

The PPD approach is notable for its avoidance of organic solvents and sophisticated equipment, potentially resulting in a reduced environmental footprint compared to traditional extraction methods. This aligns with growing industry trends towards more sustainable food processing techniques.