Wheat processor invests €18.5m in state-of-the-art silo infrastructure

In a significant move to enhance its wheat processing capabilities, Crespel & Deiters Group has embarked on its largest infrastructure investment to date. The €18.5 million project aims to bolster storage capacity and operational flexibility at the company’s Ibbenbüren site in Germany.

Crespel & Deiters Group, a leading European producer of wheat starches and proteins, has initiated construction on a cutting-edge silo facility at its headquarters in Ibbenbüren, Germany. This substantial investment, announced in August 2024, represents a strategic move to fortify the company’s position in the competitive wheat processing industry.

The new silo building, slated for completion in early 2026, is set to significantly expand the company’s storage and handling capabilities. With a capacity of approximately 2,000 tonnes, the facility will comprise 18 silo cells equipped with state-of-the-art technology. This development is part of a broader strategy to enhance operational efficiency and maintain the company’s commitment to product quality and customer service.

Steffen von Glahn, COO of the Crespel & Deiters Group, emphasised the strategic importance of the investment: “The functionality and development of our sites form the basis of our global operations. The Ibbenbüren location is the foundation of our activities, as this is where the primary processing and refining processes take place. Investing in infrastructure is a clear commitment to our headquarters in increasingly uncertain circumstances.”

Construction techniques

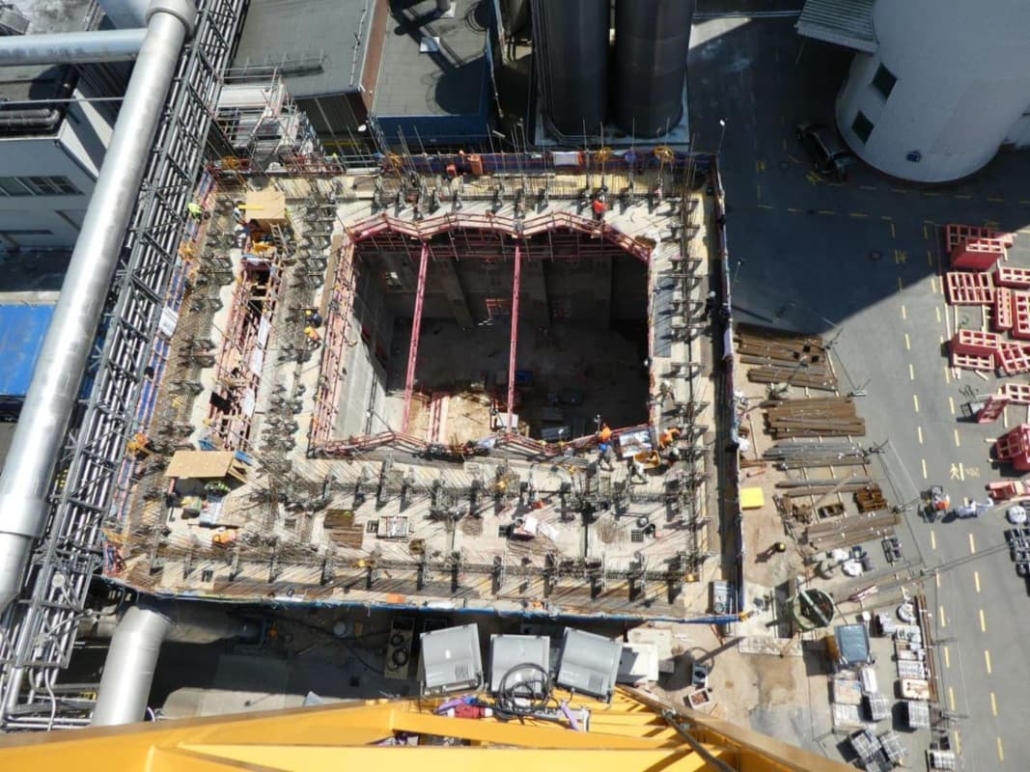

The construction process itself is noteworthy from an engineering perspective. The project began with the removal of four smaller silos to make way for the new structure. The shell of the building was created using slipform construction, an efficient technique where concrete formwork is continuously raised as the building grows. This method allowed the exterior facade to be completed within a mere two weeks, showcasing the rapid progress of modern construction techniques in industrial settings.

Integration with existing facilities

This latest investment builds upon recent upgrades to the Ibbenbüren site. In 2018, Crespel & Deiters established the MT facility, which combines raw material storage, loading bridges, and machinery for flour storage and separation. Following this, in 2021, the company commissioned an A-starch dryer, designed with a focus on energy efficiency, hygiene, and operational reliability.

The integration of these facilities with the new silo building is expected to create synergies that will enhance the entire production process. This holistic approach to infrastructure development presents an interesting case study in optimising wheat processing operations.

Sustainability and regional partnerships

In line with contemporary food industry trends, Crespel & Deiters has placed a strong emphasis on sustainability and local partnerships in this project. The company’s commitment to using EU wheat, with at least 75% sourced from German cultivation, underscores its focus on reducing transport emissions and supporting local agriculture.

Moreover, the decision to collaborate with regional partners for the silo construction project reflects a strategy to strengthen local supply chains. This approach not only benefits the regional economy but also potentially increases the resilience of the company’s operations in the face of global supply chain disruptions.

Implications for the food industry

For food scientists, this investment signals several important trends in the wheat processing sector:

- Capacity expansion: The significant increase in storage capacity suggests an anticipation of growing demand for wheat-based ingredients in various food applications.

- Technological advancement: The integration of state-of-the-art technology in the new silo facility indicates a move towards more precise control over storage conditions, potentially leading to improved ingredient quality and consistency.

- Vertical integration: By enhancing its storage and handling capabilities, Crespel & Deiters is strengthening its control over the supply chain, which could lead to more efficient operations and potentially more competitive pricing for wheat-derived ingredients.

- Sustainability focus: The emphasis on local sourcing and partnerships aligns with broader industry trends towards reducing carbon footprints and enhancing supply chain transparency.

As the project progresses towards its 2026 completion date, industry observers will be keen to see how this significant investment impacts Crespel & Deiters’ product offerings and market position. The company’s focus on wheat starches and proteins places it at the intersection of several key trends in food science, including clean label formulations, plant-based proteins, and functional ingredients.

This investment by Crespel & Deiters Group represents more than just an expansion of storage capacity; it’s a strategic move that could potentially influence the dynamics of the wheat processing industry in Europe. As the facility comes online, its impact on product quality, operational efficiency, and market competitiveness will be areas of keen interest for food scientists and industry professionals alike.