Why smart fill level adjustment is key to reducing waste and protecting margins

Frank Borrmann, Market Manager for the Strategic Business Unit Checkweighing & Vision, Mettler-Toledo Garvens GmbH, looks at how smart fill level systems use real-time weight data to slash production waste. Advanced feedback technology automatically fine-tunes filling processes, cutting excess product giveaway from 0.69% to 0.14% whilst maintaining quality standards. This intelligent automation tackles rising material costs through precision control, delivering measurable returns within months across high-speed manufacturing lines.

There is no prestige in giving away product. Yet across production lines everywhere, that is exactly what happens when filling processes are left to drift. A few extra grams here, a wider tolerance there, and it quickly adds up. As raw materials grow more expensive and sustainability targets become sharper, more manufacturers are turning to fill level adjustment as a smarter way to close the gap between target weight and actual pack contents.

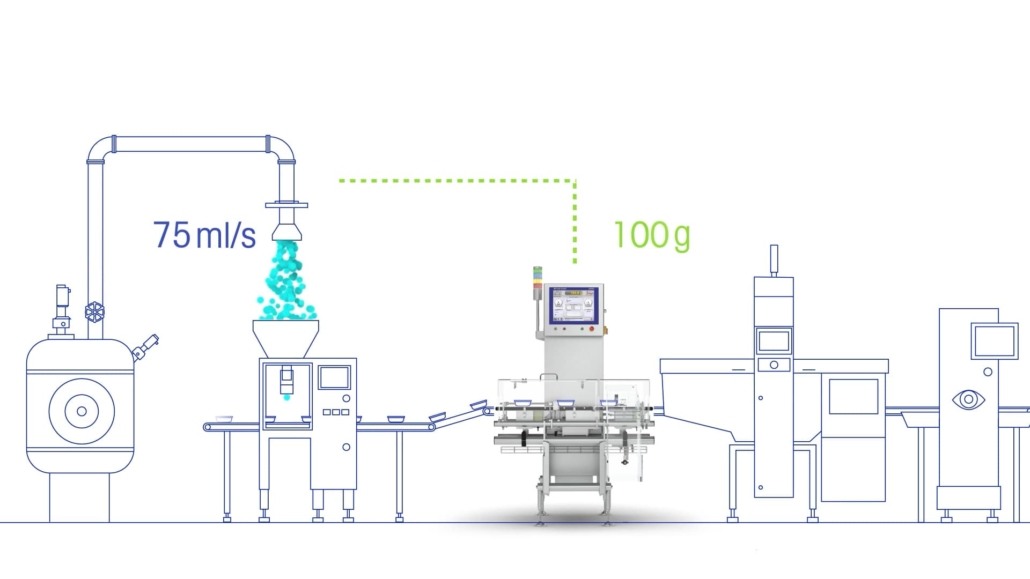

Smart fill level adjustment uses dynamic feedback from checkweighers to automatically regulate filling equipment in real time. Rather than relying on manual checks or occasional adjustments, the system monitors the average weight of a series of packs and instructs upstream filling machines and multi-head weighers to make micro-corrections. The result is a tighter weight distribution, reduced product giveaway and more consistent pack quality.

This approach is especially valuable in high-speed environments where small inefficiencies compound quickly. It is already being adopted across a range of industries, from frozen food to snacks and confectionery. The common denominator is a shift in mindset, from accepting giveaway as a cost of doing business to actively managing it with intelligent automation.

The case for tighter tolerances

The business case is clear. Every extra gram of product represents money lost and raw material used unnecessarily. In categories with thin margins or expensive ingredients, even minor improvements in fill accuracy can lead to substantial gains.

Traditional filling processes often rely on conservative tolerances to reduce the risk of underfilling. But this comes at a cost. Wider margins may keep lines running smoothly, but they also increase the likelihood of overpacking, particularly as machines drift over time or respond to subtle changes in product flow.

Fill level adjustment addresses this by creating a feedback loop. As the checkweigher gathers real-time data, it adjusts the filling system automatically to maintain a tighter, more predictable package weight. This not only reduces giveaway but also supports greater line stability, especially during changeovers or when dealing with variable product formats.

Making smarter use of existing technology

One of the strengths of modern fill level adjustment is that it does not require a complete overhaul of the line. In many cases, it can be integrated into existing checkweighers and filling equipment with a software upgrade and some configuration support. That makes it a cost-effective and scalable option for manufacturers looking to boost performance without introducing complexity.

“On average, the investment is recouped within a month or a few months, depending on the product and the line,” says Frank Borrmann, Market Manager for the Strategic Business Unit Checkweighing & Vision, Mettler-Toledo Garvens GmbH. “Companies realise that they can save a lot with smart technology.”

The return is not only financial. By reducing reliance on manual intervention, the system also supports consistency, frees up operator time and lowers the risk of human error. As many manufacturers face labour shortages or shifting staffing patterns, this level of automation helps build resilience into the process.

Real-world impact

At Greenyard Frozen Belgium, which produces millions of frozen fruit and vegetable packs each year, fill level adjustment has already delivered measurable improvements. One of its packaging lines reduced excess weight from 0.69 percent to 0.14 percent. On another, the figure dropped from 0.3 percent to 0.11 percent. Those numbers translate directly into reduced waste, lower costs and more efficient use of materials.

“That may not seem like much, but if you calculate it on an annual basis over large volumes, you are talking about considerable quantities of product that you no longer unnecessarily pack,” said Dominiek Vierstraete, Technical Manager at Greenyard. “That is beneficial for the cost price and for reducing waste.”

The company now uses fill level adjustment on all six of its small pack lines, a move that supports both sustainability goals and operational consistency.

Looking forward

As material costs remain volatile and consumer expectations continue to rise, manufacturers will need to find new ways to optimise their processes without compromising quality. Fill level adjustment offers a clear path forward. It addresses a known source of waste, requires minimal disruption to implement and can unlock performance gains almost immediately.

The technology is also evolving. As communication between systems becomes more streamlined and visual interfaces improve, operators gain even more transparency into line performance. “You can immediately see how the average weight develops via a visual interface,” said Vierstraete. “After a few hours of testing and adjustments, the system runs stably.”

For manufacturers ready to take tighter control of their line efficiency, fill level adjustment is no longer a niche add-on. It is fast becoming a standard expectation in high-performing production environments.

- For more information, visit: Fill Level Inspection and Control | METTLER TOLEDO

or mt.com/filllevel-pr