Yeast protein discovery offers novel alternative to traditional food emulsifiers

Researchers have identified specific yeast cell wall proteins that demonstrate emulsifying properties comparable to milk-derived casein, potentially offering a new allergen-free alternative for food manufacturing. The discovery of these easily extractable proteins, particularly Tdh2 and Fba1, marks a significant advancement in developing natural, sustainable emulsifiers from microbial sources, addressing growing industry demands for non-allergenic ingredients.

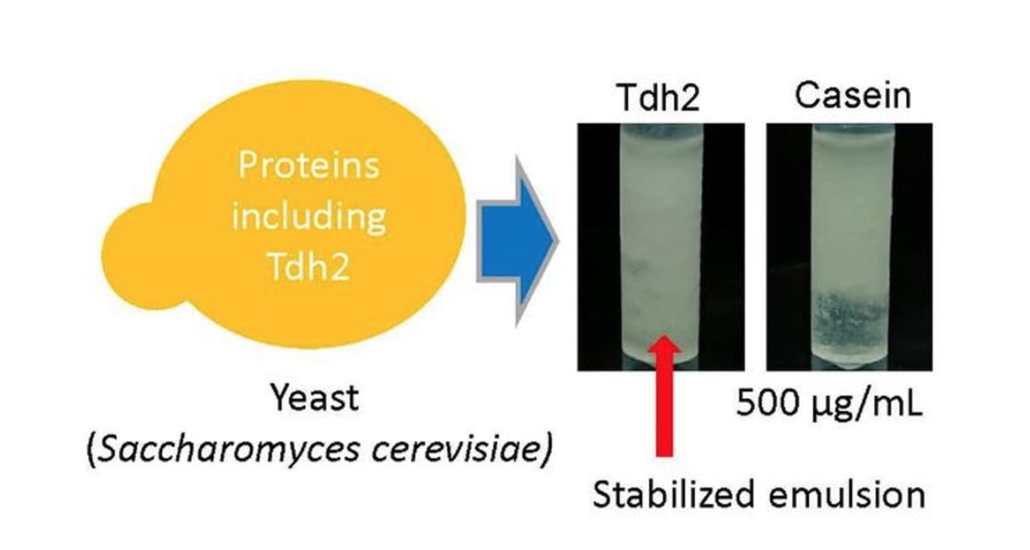

The yeast-derived protein Tdh2 displays emulsifying properties comparable to milk-derived casein. © Osaka Metropolitan University

Japanese researchers at Osaka Metropolitan University have successfully isolated and characterised several glycolytic proteins from Saccharomyces cerevisiae that exhibit strong emulsifying properties. Their comprehensive analysis, published in Food Hydrocolloids, reveals that these proteins, particularly Tdh2, demonstrate effectiveness comparable to commercial milk-derived emulsifiers, potentially revolutionising food manufacturing processes.

The research team’s systematic approach led to the identification of multiple proteins including Fba1, Eno1, Eno2, and most notably Tdh2. Previous research had identified Gas proteins (Gas1, Gas3, and Gas5) as effective emulsifiers, but these were strongly bound to cell walls, making extraction challenging. The newly identified proteins, in contrast, can be easily released from yeast cells, offering significant practical advantages for industrial applications.

Structural advantages

What makes Tdh2 particularly interesting is its molecular structure. Comprising 332 amino acids with a predicted molecular weight of 35.8 kDa, the protein shows minimal glycosylation and contains only two cysteine residues, resulting in fewer disulfide bonds compared to traditional yeast-derived emulsifiers like Gas1. This simpler structure may contribute to its effectiveness and could simplify production processes.

The protein maintained stable emulsification across a broad pH range, though showing slightly reduced activity at pH 7, near its isoelectric point of 6.96. This stability across different pH conditions suggests versatility in various food applications.

Performance characteristics

Through extensive testing, the researchers evaluated Tdh2’s emulsifying capabilities under various conditions. The protein showed particularly strong performance with tetradecane and hexadecane, requiring lower concentrations for effective emulsification compared to shorter-chain hydrocarbons like octane.

In vegetable oil applications, Tdh2 demonstrated superior emulsion stability compared to casein, maintaining better phase separation control in soybean oil over a five-hour period. This performance characteristic suggests significant potential for food industry applications, particularly in products requiring long-term stability.

“The identification of the major emulsifying proteins in yeast cell wall components is expected to promote the use of these yeast extracts,” stated Professor Masayuki Azuma, who led the research. “By increasing the productivity of the identified proteins, we expect that they can be applied as purified emulsifying proteins.”

Industrial implications and future prospects

The discovery presents several compelling advantages for industrial applications. Yeast-based production offers rapid production times, minimal space requirements, and the potential to utilise waste yeast from brewing processes, aligning with sustainable manufacturing practices.

The proteins’ smaller molecular weight compared to traditional emulsifiers like Gas1 also offers new opportunities for studying structure-function relationships in emulsification. This could lead to further optimisation of protein-based emulsifiers and potentially the development of designer proteins with enhanced properties.

The identification of these proteins comes at a crucial time when food manufacturers are increasingly seeking alternatives to traditional emulsifiers derived from milk, eggs, and soybeans, which are common allergens. Yeast-derived emulsifiers could offer a safe, sustainable alternative while maintaining the functional properties required for food production.

Future research directions may include scaling up production, optimising extraction methods, and conducting more detailed studies of emulsion size distribution and quantitative analysis. The team suggests that understanding the relationship between protein structure and emulsification could facilitate the design of superior emulsifying agents.

Reference

Saito, D., Nerome, S., Tachiwana, M., et.al (2025). Yeast cell wall-derived proteins: Identification and characterization as food emulsifiers. Food Hydrocolloids, 160, 110746. https://doi.org/10.1016/j.foodhyd.2024.110746