Future Meat Technologies raises $347 million in Series B financing round marking the largest investment in cultivated meat

Future Meat Technologies, (Future Meat), an industry-leading company developing innovative technology to produce cultivated meat, has raised $347 million in a Series B round of financing.

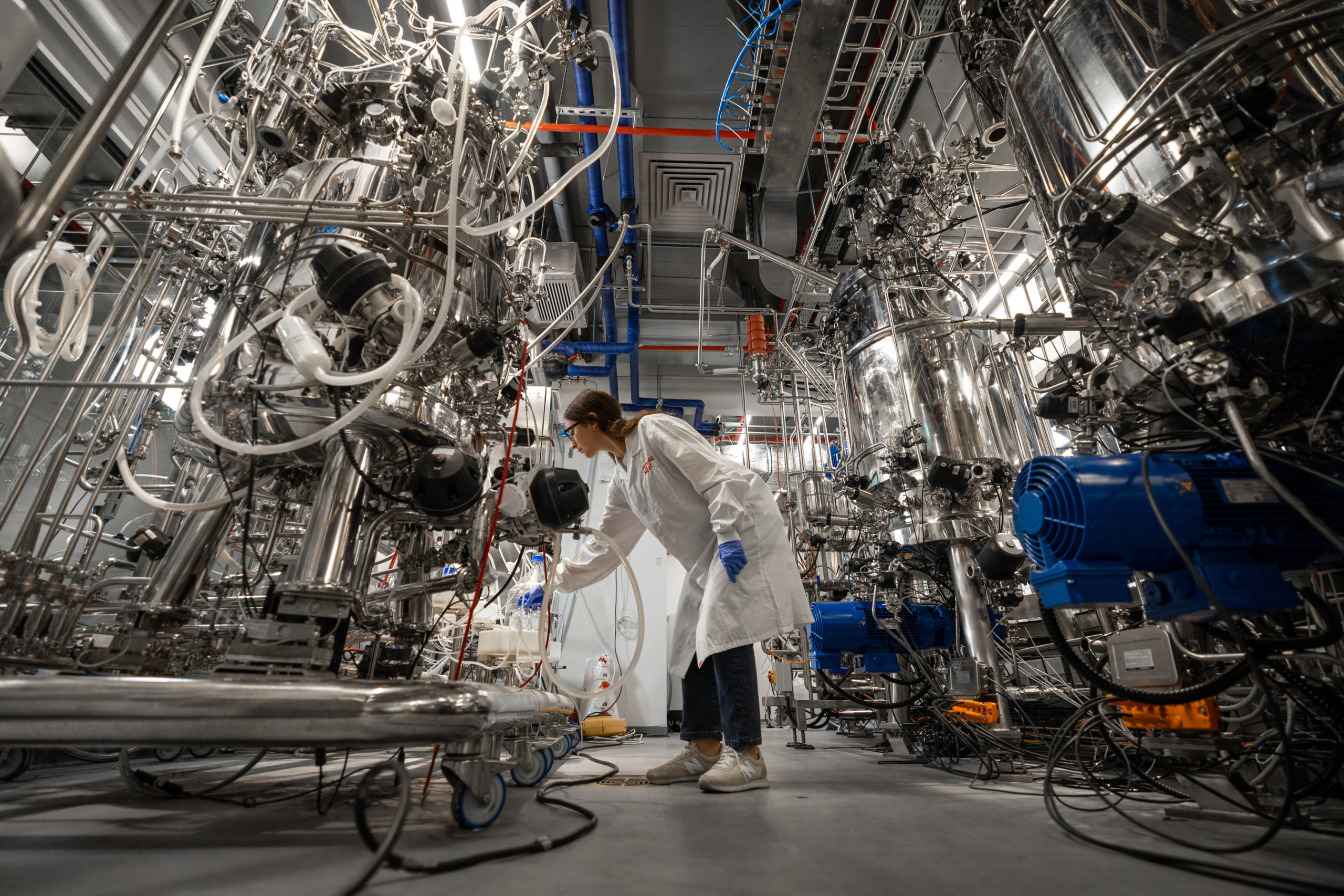

In June last year, the company opened the world’s first industrial cultured meat facility in Israel and is scouting for locations in the United States. With the capability to produce 500kg of cultured products a day, equivalent to 5,000 hamburgers, this facility makes scalable cell-based meat production a reality. The facility can produce cultured chicken, pork and lamb, without the use of animal serum or genetic modification (non-GMO). The production of beef is expected soon.

The facility further supports Future Meat Technologies’ larger efforts to create a more sustainable future. The company’s cruelty-free production process is expected to generate 80% less greenhouse emissions and use 99% less land and 96% less freshwater than traditional meat production.

The Series B funding round was co-led by ADM Ventures, the venture investing arm of ADM, a global leader in human and animal nutrition. It also included participation from a global investor in leading technology companies, the Menora Mivtachim pension and insurance fund which manages over $85 billion in assets, and S2G Ventures, among others. The company noted these investors represent massive support from key players in North America, Europe, and Asia.

“We are incredibly excited by the massive support of our global network of strategic and financial investors,” said Professor Yaakov Nahmias, founder and president of Future Meat. “This financing consolidates Future Meat’s position as the leading player in the cultivated meat industry, just three years after our launch. Our singular technology reduced production costs faster than anyone thought possible, paving the way for a massive expansion of operations.”

The company will break ground on the first-of-its-kind, large-scale production facility in the United States later this year.

Ian Pinner, senior vice president of strategy and innovation, ADM, said: “We’re excited to expand our relationship with Future Meat and expand the universe of new sources of protein to consumers who are increasingly diversifying their diets. Partnerships like these are one of the key ways ADM is creating and capturing new value in growth segments like alternative proteins, and we’re eager to support the Future Meat team in their efforts to continue developing groundbreaking solutions that will provide high-quality and scalable cultivated meat products to consumers in the years to come.”

“While Future Meat is leading the pack as the fastest growing company in this space, I truly see the entire cultivated meat industry as a massive agent of change, creating a sustainable future for coming generations,” added Prof. Nahmias.

“We have consistently demonstrated that our single-cell technology and serum-free media formulations can reach cost parity faster than the market anticipates,” added Prof. Nahmias, who previously described the space as the Apollo program of the 21st century. “We also demonstrated that our proprietary media rejuvenation techno-

logy enables cell densities greater than 100 billion cells per litre, translating to production densities 10-times higher than the industrial standard.”

“It is our mission to create a more sustainable future for coming generations. Our technology can produce meat on a fraction of the land currently used for meat production,” said Prof. Nahmias.

Future Meat’s proprietary technology is based on stainless steel fermenters which continuously remove waste products generated by “immortal” tissue cells. This allows the company to maintain a constant physiological environment which supports rapid, natural, proliferation of animal cells. The company proved that this connective tissue method is more robust and efficient than others using stem cells, and that its rejuvenating fermenters can recycle over 70% of the nutrients. It is also currently the most cost-efficient manner available, a key factor enabling Future Meat’s industry-leading low costs, which has been the largest hurdle in bringing cultivated meat to cost parity with traditional meat.