Coperion introduces MEGAtex cooling die for manufacturing plant-based meat substitutes

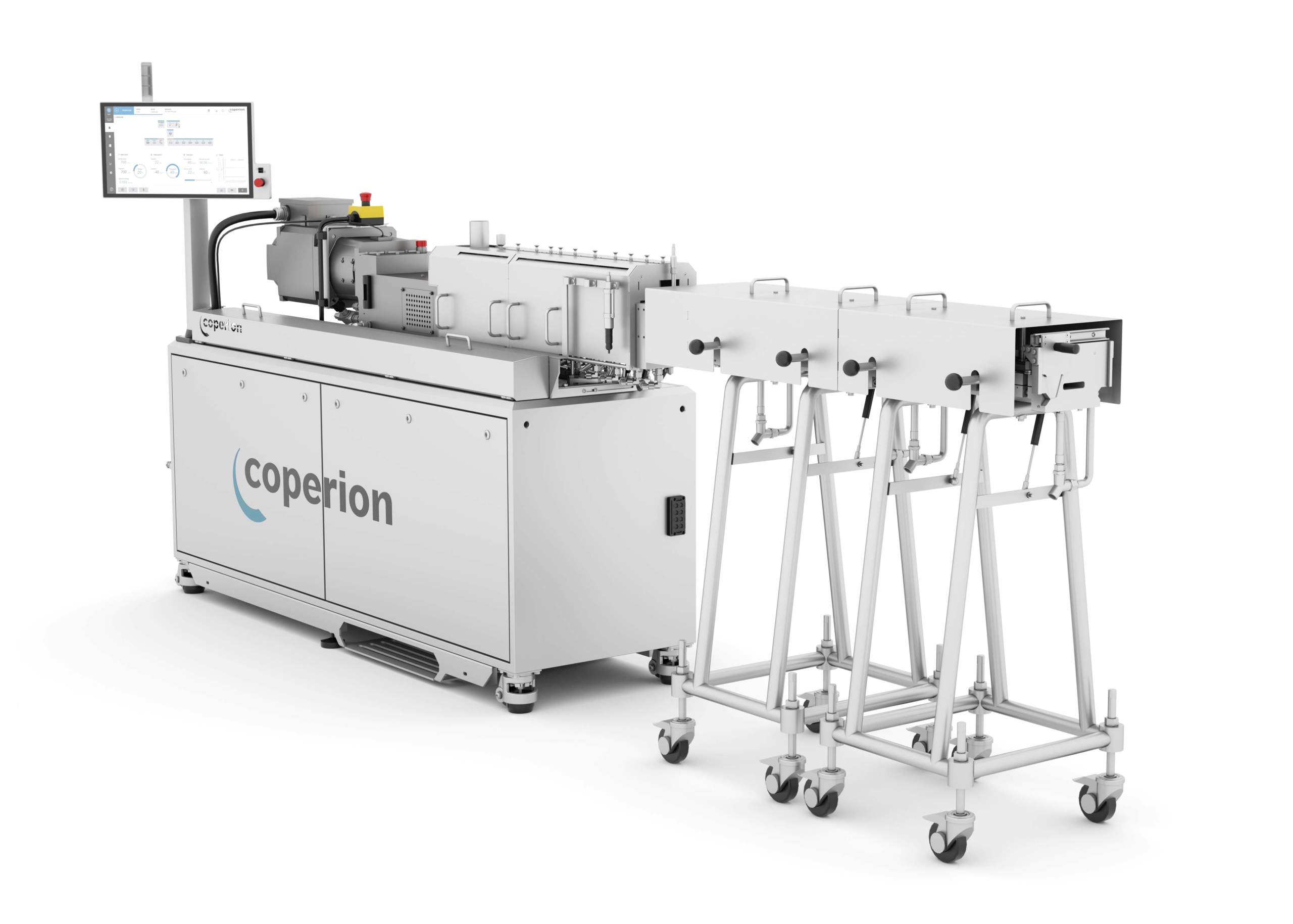

Coperion has developed the new MEGAtex S7 cooling die for manufacturing plant-based HMMA (High Moisture Meat Analogue) meat substitutes. Mounted at the discharge of the ZSK Food Extruder, this texturizing unit gives the plant protein mass a dense, fibrous structure that closely resembles animal flesh.

For many years, Coperion has been a proven supplier of production systems for plant-based meat substitute products. With the MEGAtex S7 cooling die, Coperion has developed a new discharge for HMMA production that allows for variable width and strength as well as various textures for meat substitutes. Moreover, Coperion has equipped the MEGAtex cooling die with features that simplify handling and make both recipe and configuration changes possible with just a few quick adjustments.

HMMA is a plant-based intermediate product that is primarily used for ready-to-eat meals such as vegan chicken nuggets or ground meat. It contains 50 to 70 percent water and 30 to 50 percent plant proteins with less than 10 percent fat content. In the HMMA manufacturing process, protein-rich raw materials are first mixed with water and worked into a homogeneous mass in a ZSK Food Extruder. This mass is then pressed through the MEGAtex cooling die, where the meat-like texture is formed, and a solid strand is discharged for further processing.

Characteristics of HMMA quality are the product’s texture and strength as well as the length and strength of the fibres. Coperion developed this new texturizing unit in order to more precisely fulfil these quality requirements, and in particular to provide more flexibility to smaller companies, research organizations, and startups. The MEGAtex S7 achieves throughputs of 5 to 50 kg/h and can currently be combined with the ZSK Food Extruder sizes 18, 27 and 34. Additional sizes of the Coperion MEGAtex cooling die for significantly higher throughputs will follow.

The MEGAtex cooling die features a modular design. It consists of individual segments which can be combined as needed, depending upon the requirements of the raw materials and the desired product structure.

The MEGAtex S7 comes with interchangeable inlays that give the machine operator the flexibility to vary the strand width between 35 and 70 mm and the length between 10 and 15 mm. Just a few simple steps are all that is needed to open the cooling die and exchange the inlays.

Such easy handling is also a great advantage when changing recipes or extracting product samples. With its clever opening mechanism, the MEGAtex cooling die provides optimal access along its entire length. Moreover, product samples can be extracted at any time in any segment of the cooling die. The MEGAtex also features a hygienic design which reduces machine downtime for cleaning to a minimum.

At the end of the die, there is a special cutter to facilitate quick sampling of HMMA at the discharge.

The cooling die is mounted on rollers, making it mobile. These additional features make the MEGAtex especially flexible when frequently changing products, and ideal for development environments.

“The market for plant-based meat substitutes is growing exponentially and it’s very important to us to propel this development forward with innovative technologies. With this new MEGAtex cooling die, we’re pursuing our goal of redesigning the HMMA manufacturing process with greater variability. Moreover, maximized accessibility will markedly reduce cleaning time and increase the overall profitability of HMMA production. After comprehensive tests at our Food Test Lab using various raw materials, we can confirm with high certainty that we have fully achieved these goals,” said Markus Schmudde, Head of Research and Development, Compounding & Extrusion at Coperion.

Coperion will exhibit the new MEGAtex S7 cooling die at Anuga FoodTec 2024 (19-22 March, 2024, Cologne, Germany) at booth B-011 in Hall 10.1.

For more information, visit: www.coperion.com