Döinghaus unveils new automated food processing solution at iba 2025

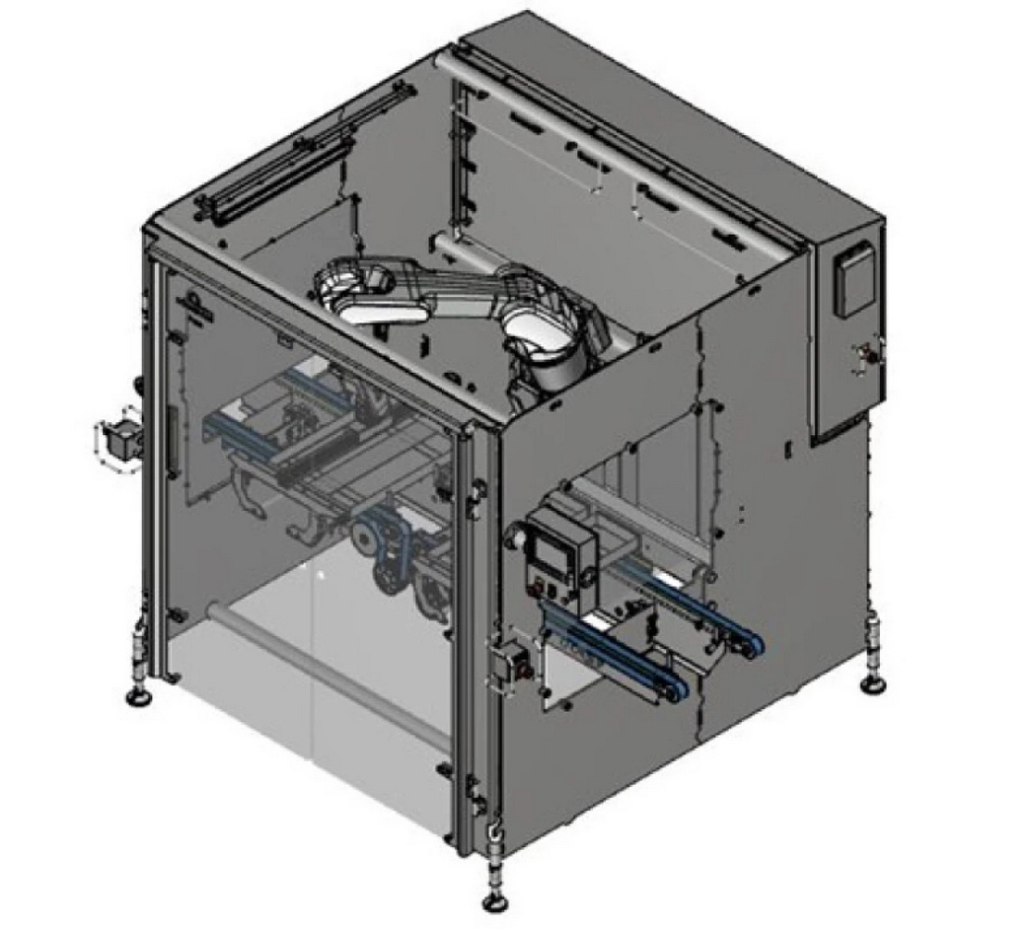

German ultrasonic cutting specialist Döinghaus cutting and more GmbH & Co. KG showcased their latest innovation in process automation, the IQ-Move Peon, at iba 2025. The technology, designed to streamline production workflows, aims to enhance precision and efficiency in food manufacturing by automating the product placement process following ultrasonic cutting operations.

Automation advances in ultrasonic food cutting

Döinghaus cutting and more GmbH & Co. KG presented their newest technological development, the IQ-Move Peon, at iba 2025. The machine represents a significant advancement in food processing automation, specifically designed to handle products post-cutting.

The IQ-Move Peon has been engineered to automate the transport and placement of food products after they have undergone ultrasonic cutting. The system can place products onto presentation sheets, into boxes, or on mats and trays, depending on the specific production requirements.

“With the IQ-Move Peon, we offer our customers a solution that not only saves time and resources, but also delivers the highest precision with consistent quality,” explains Erik Döinghaus, Managing Director of Döinghaus cutting and more GmbH & Co. KG. “Our customers can be sure that their production processes are optimized, which ultimately leads to greater efficiency.”

Integration capabilities and technical specifications

A key attribute of the IQ-Move Peon is its ability to integrate into existing production lines. The technology has been designed with adaptability in mind, allowing for customisation to meet specific production parameters and requirements.

The system’s primary function is to reduce manual handling during the post-cutting phase of food production. By automating this aspect of the process, Döinghaus aims to address several common production challenges simultaneously.

Quantifiable benefits for food manufacturers

Implementation of the IQ-Move Peon offers multiple measurable advantages for food manufacturing operations. The automated transport system significantly reduces the need for manual intervention in the production process, which in turn decreases the potential for human error and cross-contamination. The reduction in manual handling also translates to decreased labour requirements for repetitive tasks, potentially allowing for reallocation of human resources to more complex operations that require decision-making capabilities or quality assessment. Additionally, the precision offered by the automated system ensures consistent product placement, which may contribute to improved packaging efficiency and product presentation.

Focus on seamless process automation

The development of the IQ-Move Peon aligns with increasing industry demand for end-to-end automation solutions in food processing. By addressing the transport phase between cutting and packaging, Döinghaus has targeted a common production bottleneck.

Customisation for specific production requirements

Döinghaus emphasises their approach to developing “tailor-made machine and plant solutions” that address individual requirements and preferences.

For more information, visit:www.cuttingandmore.de

Digital issue: Please click here for more information