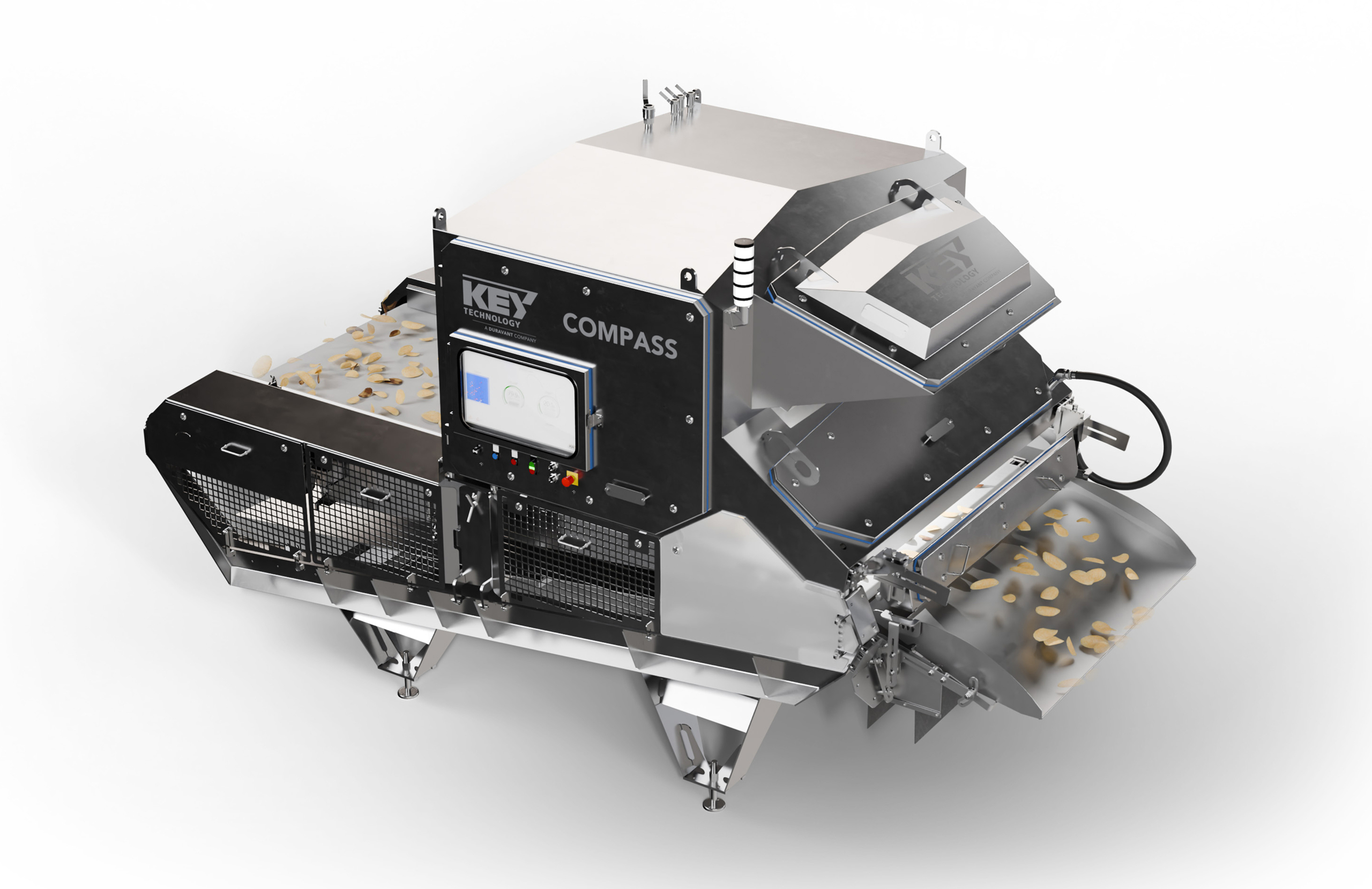

Key Technology unveils COMPASS optical sorter for snack food applications

Key Technology has introduced its COMPASS optical sorter for chips at Pack Expo Las Vegas, marking a significant development in automated quality control systems for the snack food industry. The belt-fed sorting platform has been engineered specifically for potato chips, tortilla chips and related products, with capabilities extending to extruded snacks, pellets and specialty items such as sesame sticks.

Advanced detection capabilities

The system utilises Key’s NEXT sort engine technology, incorporating customisable camera options and up to eight channels of multispectral sensor data. This configuration enables detection of colour, size, shape and structural properties of individual objects, facilitating identification of product defects including dark spots, green discolouration and white knot bruises, alongside foreign material such as fryer debris.

“Key has been at the forefront of potato chip sorting and handling technology for decades, and COMPASS represents the next evolution in our commitment to this industry,” said Jack Lee, Duravant Group President – Food Sorting and Handling. “We’ve leveraged our extensive applications expertise to develop innovations that address the real operational challenges of chip processors, including automatic belt tracking, intuitive controls and clean-in-place features for extended run times between sanitation cycles.”

Operational efficiency features

COMPASS incorporates recipe-driven programming with a smartphone-style user interface, enabling operators to create and modify sorting parameters with minimal technical expertise. The manufacturer claims new operators can achieve production competency within 30 minutes of training. Intelligent belt control systems automatically maintain proper tracking whilst compen-sating for belt dimensional changes, reducing manual intervention requirements.

The system’s sanitation design features open architecture, sloped surfaces and minimal moving components. Sensors and optical windows are positioned to avoid product contamination, whilst stain-resistant belt technology maintains inspection accuracy during extended production runs. Specialised collection systems utilise counter-rotating brushes or scrapers to direct oil and debris into removable bins, with washdown cycles achievable within 15 minutes.

Data analytics integration

Each COMPASS unit incorporates Key Discovery software, transforming the sorter into an Industrial Internet of Things-connected device. The platform provides detailed product quality and process data, offering insights into production operations, quality trends and upstream process optimisation opportunities including fryer parameter adjustments.

Multiple configurations are available to accommodate varying application requirements and processing capacities, with options for integrated infeed and discharge conveyor systems.

For more information, visit: www.key.net/en/our-products/sorting

Digital issue: Please click here for more information