Regal Rexnord addresses critical hygiene and precision requirements in beverage manufacturing

Regal Rexnord has introduced an integrated portfolio of mechanical and automation solutions specifically engineered to meet the stringent operational demands of beverage production and bottling lines, where high-speed processing, washdown protocols, and precision control present ongoing technical challenges.

Specialised components for harsh processing environments

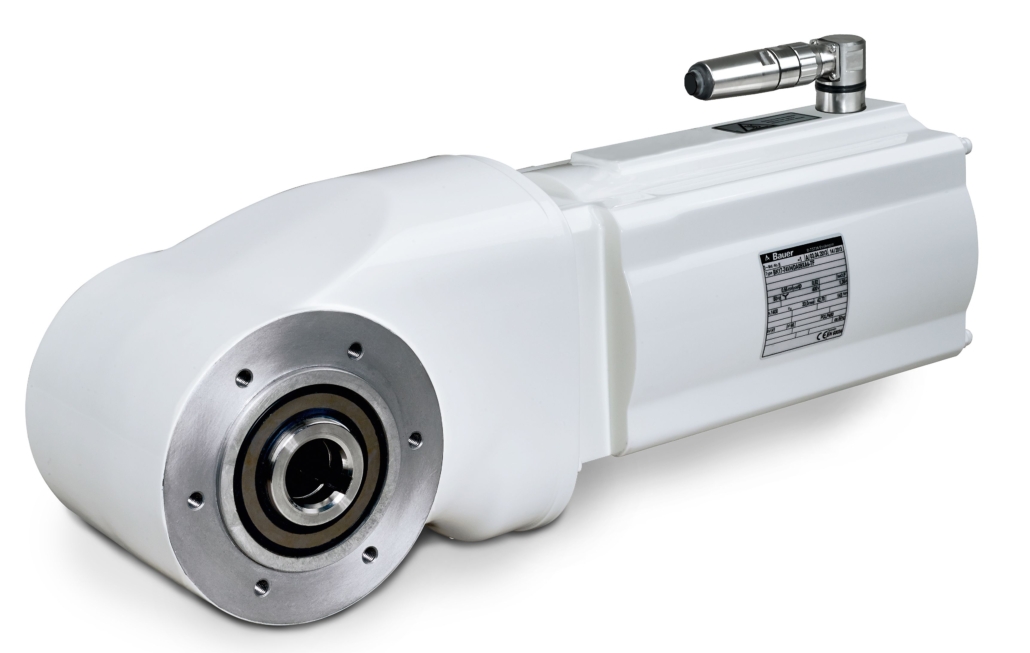

The company’s product suite addresses key technical requirements in beverage manufacturing, including resistance to corrosive washdown procedures and maintenance of operational precision under continuous production cycles. The Bauer Gear Motor range features hygienic drives designed for harsh washdown environments, whilst Sealmaster bearings provide enhanced sealing and corrosion resistance in wet or acidic conditions typical of drinks production facilities.

Kollmorgen washdown-ready servo motion systems incorporate stainless steel and anodised aluminium construction to withstand frequent cleaning protocols whilst maintaining positioning accuracy for bottling and capping operations. The direct drive technology eliminates mechanical backlash, enabling real-time adjustments that support consistent fill levels and regulatory compliance for labelling requirements.

Regal Rexnord’s brand portfolio includes Bauer Gear Motor, which offers specialized hygienic drives for hygienic applications.

Integration of motion control and power transmission systems

The integrated approach encompasses mechanical power transmission, linear motion control, and electromagnetic braking systems within a unified supplier framework. Thomson precision linear actuators and guides provide repeatable movement for fill-level consistency and label alignment, whilst electromagnetic clutches and brakes enable rapid response times during frequent start-stop cycles required for conveyor indexing and cap placement processes.

Operational efficiency through component compatibility

The consolidated supplier model addresses procurement complexity by providing component compatibility across gear motors, conveyors, servo systems, bearings, and braking mechanisms. This integration strategy reduces logistical coordination requirements and supports system-level compatibility throughout equipment lifecycles.

The company’s three operating segments – Industrial Powertrain Solutions, Power Efficiency Solutions, and Automation & Motion Control – serve beverage manufacturing alongside discrete automation, aerospace, medical, data centre, and other industrial sectors. With manufacturing and service facilities distributed globally, the company maintains technical support infrastructure for both original equipment manufacturers and end users implementing new production lines or upgrading existing installations.

For more information, visit: https://www.regalrexnord.com

Digital issue: Please click here for more information

High-speed production lines require dependable driveline components for reliable manufacturing output.