TNA Solutions unveils complete potato chip line at European open house

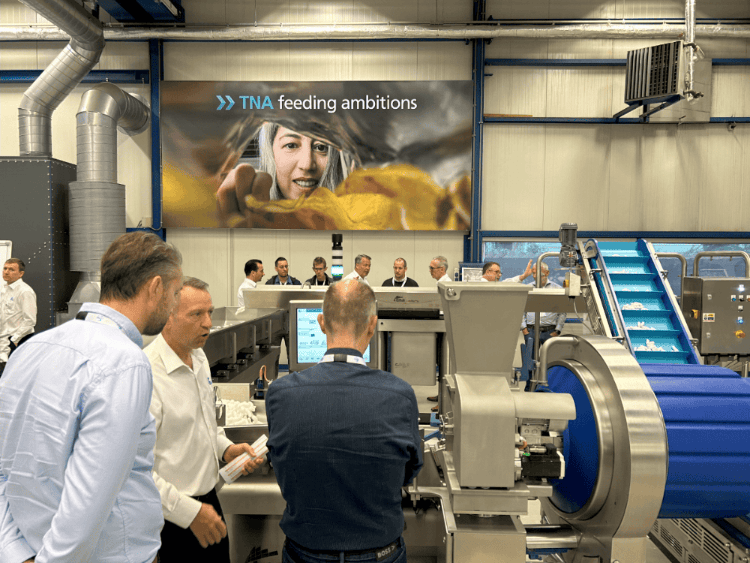

TNA Solutions, a global provider of food processing and packaging solutions, has showcased its integrated potato chip production technology at its manufacturing facility in Woerden, The Netherlands. The event, held from 23-26 September 2024, offered European customers a first-hand look at the company’s end-to-end capabilities in snack production.

The centrepiece of the open house event was a fully operational potato chip production line, demonstrating TNA’s range of solutions from seasoning to distribution and packaging. This integrated system highlighted the company’s unique position as the sole global provider offering a complete potato snack production line from a single source.

Visitors from 12 countries attended the event, witnessing live demonstrations of the production line. The showcase emphasised TNA’s ability to address the entire manufacturing process, from initial processing to final packaging.

Innovation centre supports product development

The open house also introduced attendees to the TNA Innovation Centre, formerly the manufacturing facility of Florigo International B.V., which TNA acquired in 2015. This centre now serves as a hub for advanced food processing solutions, supporting manufacturers worldwide.

Eric Geling, Chief Sales Officer at TNA Solutions, explained the rationale behind the event: “Snack producers continually need to meet the growing and changing demands of customers to remain competitive. For example, a recent UK survey found that customers were turning to healthier snack options, with 2023 spending increasing 39% on the previous year. Snack manufacturers that can adapt faster are better positioned to provide customers with the products they want, ahead of their competitors.”

Geling added: “Ultimately, consumers are looking for healthier, affordable and novel snacks that still boast a captivating taste profile. The chip market is a prime example of this – Europe accounts for the second largest market for non-potato veggie chips, due to consumers seeking healthier options.”

Addressing market trends

The event highlighted how TNA’s solutions can help manufacturers respond to evolving consumer preferences. With the growing demand for healthier snack options, flexibility in production has become increasingly important. TNA’s integrated systems aim to provide this flexibility while maintaining high output volumes and lower total cost of ownership.

The TNA Innovation Centre offers manufacturers the opportunity to collaborate on new product development, allowing them to test and refine products in response to market trends. This capability is particularly relevant given the recent surge in demand for healthier snack alternatives, including non-potato vegetable chips.

TNA’s approach of offering complete line solutions suggests a trend towards more integrated manufacturing processes in the food industry. This integration can potentially offer benefits in terms of process control, efficiency, and the ability to quickly adapt to changing market demands.

- Explore TNA’s complete line solutions for potato chip production:

tnasolutions.com – potato-chips-full-line