Hosokawa Alpine launches ADM classifier mill for fine powder production

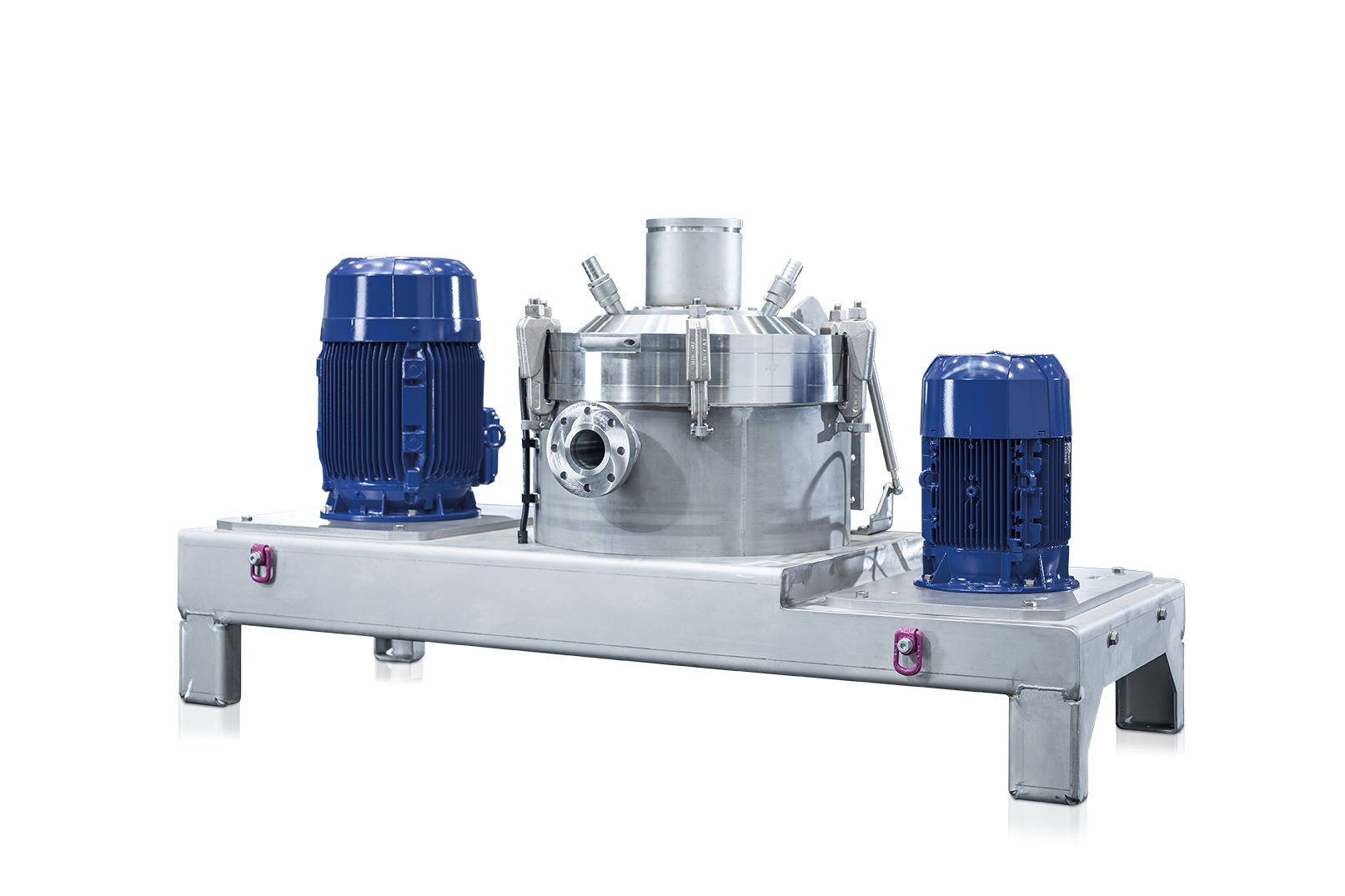

Hosokawa Alpine AG has introduced the Alpine Dual Mill (ADM), a new classifier mill that combines features from the company’s existing ACM and ZPS mill series to offer enhanced flexibility for processing applications in the chemical and food industries.

Ultra-fine grinding with modular design

The mill is designed to produce ultra-fine powders with upper particle sizes in the single-digit micrometre range. According to the manufacturer, the equipment achieves particle size distributions of d97 below 7 micrometres at impact edge speeds of up to 135 metres per second.

The ADM will be available in four different sizes, with variants for both very fine and medium-fine products. A key feature is its modular approach to classification, which incorporates both established classifier wheels and newly developed fine separating classifier wheels.

“The new classifier mill can be operated with three different classifier wheel geometries for specific requirements and maximum fineness, making the range of applications very flexible for our customers,” said Daniel Droop, senior R&D manager at Hosokawa Alpine.

Operating principles and efficiency

The mill operates using a pneumatic or screw conveyor feeding system. Size reduction occurs through impact of the material on rotating grinding elements and a stationary grinding track. Processing air drawn through the mill by a downstream fan captures the material and guides it along guide vanes in the grinding chamber.

An integrated dynamic classifier separates coarse and fine material based on opposing forces and particle mass differences. Oversized particles are rejected by the classifier wheel and returned to the grinding zone, whilst fine product passes through and exits the chamber. The separation limit can be adjusted during operation via classifier wheel speed.

The manufacturer reports that the ADM achieves higher throughput compared to the ACM and ZPS mills when using equivalent drive power. The system also features low pressure loss during operation, which contributes to energy-efficient grinding. The ease of cleaning is cited as particularly relevant for food industry applications where hygiene requirements are stringent.

The Augsburg-based company employs approximately 840 people and reported annual sales of roughly 255 million euros in the 2023/2024 fiscal year.

For more information, visit: www.hosokawa-alpine.com

Digital issue: Please click here for more information