Chinese scientists develop biodegradable cellulose film that blocks 99% oxygen and signals food spoilage

Researchers at the Chinese Academy of Sciences have developed a nanocellulose-based packaging film that combines high oxygen barrier properties with a built-in colour-change freshness indicator, offering a biodegradable alternative to multi-layer petrochemical packaging.

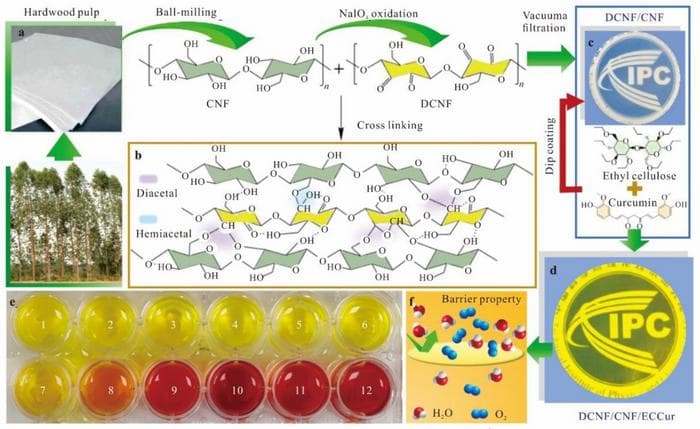

The study, published in the Journal of Bioresources and Bioproducts, describes a dual-modification approach that transforms ordinary hardwood pulp into a transparent film capable of reducing oxygen transmission by 99% whilst providing visual spoilage detection through pH-responsive colour changes.

One-step dual-engineering turns plant nanofibers into transparent plastic rival that keeps food fresh and tells consumers when it is not. © Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, Beijing, China

Dual engineering strategy

The research team, led by Min Wu at the Technical Institute of Physics and Chemistry in Beijing, employed a two-step modification process. First, cellulose nanofibres were treated with sodium periodate for one hour, cleaving C2–C3 bonds and introducing aldehyde functional groups. When mixed at a 75:25 ratio with unmodified nanocellulose and vacuum-filtered, these dialdehyde fibrils formed hemiacetal bridges that created a dense, cross-linked network structure.

The second modification involved dip-coating the film with a 3% ethyl cellulose solution containing curcumin—the polyphenolic compound responsible for turmeric’s yellow colour. This coating added a 2 µm hydrophobic layer that serves multiple functions: UV absorption, antimicrobial activity, and pH-responsive colour indication.

Barrier and mechanical performance

Testing revealed substantial improvements in gas barrier properties. Oxygen transmission rate decreased from 829 to 6.89 cm³/(m²·d·0.1 MPa), placing the material’s performance below that of polyethylene terephthalate and competitive with ethylene-vinyl alcohol barriers used in premium meat packaging. Water vapour transmission dropped 44% to 43 g/(m²·d), whilst the water contact angle increased to 95.6°, indicating enhanced hydrophobicity.

The composite film demonstrated dry tensile strength of 87.9 MPa and maintained 18 MPa wet tensile strength—outperforming both pure nanocellulose and pure dialdehyde cellulose films.

Antimicrobial and indicator functions

Laboratory testing showed the curcumin-coated film achieved greater than 99.9% antibacterial efficacy against both gram-negative Escherichia coli and gram-positive Staphylococcus aureus. The antimicrobial effect derives from a combined mechanism of aldehyde-mediated protein cross-linking and curcumin’s membrane disruption properties.

The film’s antioxidant capacity proved equally notable, scavenging 91% of DPPH free radicals within 30 minutes—sufficient to slow lipid oxidation in fatty foods.

Freshness monitoring capability

When 5 g of peeled shrimp were sealed with the film at 6°C, microbial spoilage released ammonia that raised surface pH from 6.8 to 8.1 within 36 hours. This pH shift triggered curcumin’s keto-enol tautomerism, changing the film from yellow to orange-red. Colour-space analysis recorded a ΔE value of 34 – well above the 12-unit threshold detectable by the human eye.

The colour response proved reversible, with the indicator maintaining function after ten cycles between ammonia and acetic acid vapours, suggesting potential for warehouse reuse applications.

Commercial potential

Life-cycle modelling indicates the material is home-compostable within six weeks and costs approximately USD 1.20 per kilogram at pilot scale, below the cost of multilayer ethylene-vinyl alcohol films.

“If we can replace even 5% of China’s 25 million t y⁻¹ plastic flexible packaging, that is a win for both carbon and food safety,” noted lead investigator Min Wu.

The research team reports ongoing negotiations with two major e-commerce platforms to trial the packaging for fresh noodles and ready-to-cook seafood. Future work will explore anthocyanin blends for acidifying meat products, potentially enabling a traffic-light colour system for consumer freshness indication.

Reference

Yao, R., Wang, C., Xu, Y., et al. (2025). High-barrier cellulose-based packaging material for enhanced food preservation with visual freshness monitoring. Journal of Bioresources and Bioproducts. Advance online publication. https://doi.org/10.1016/j.jobab.2025.11.003