Novel SERS sensor wrapper enables real-time food quality monitoring and preservation

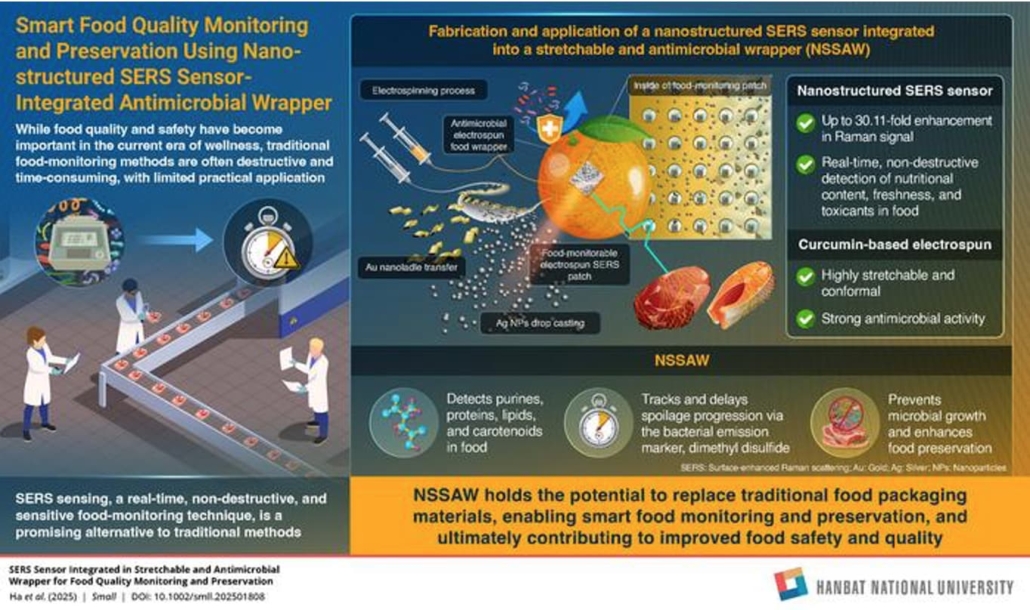

Researchers at Hanbat National University have developed a dual-function food packaging system that combines surface-enhanced Raman scattering (SERS) sensing technology with antimicrobial properties. The nanostructured wrapper enables real-time, non-destructive detection of nutritional components and spoilage markers whilst actively preserving food through curcumin-based antimicrobial action.

A team led by Associate Professor Ji-Hwan Ha from the Department of Mechanical Engineering at Hanbat National University, Republic of Korea, has created a nanostructured SERS sensor integrated into a stretchable and antimicrobial wrapper (NSSAW) that addresses critical limitations of conventional food monitoring methods. The research, published in the journal Small, presents a packaging solution that simultaneously monitors food quality and extends shelf life.

Researchers propose a novel nanostructured SERS sensor integrated into a stretchable and antimicrobial wrapper for food quality monitoring and preservation. . © Prof. Ji-Hwan Ha from Hanbat National University, Republic of Korea

Advanced sensing capabilities for nutritional analysis

The wrapper incorporates Au nano-arrays loaded with Ag nanoparticles, delivering up to 30.11-fold Raman enhancement. This configuration enables real-time, non-destructive detection of multiple nutritional components, including purines, proteins, lipids, and carotenoids. The system can also detect pesticide residues such as thiram on meats, fish, and fruit surfaces.

Traditional food monitoring methods, including ribotyping and polymerase chain reaction, are destructive and time-consuming, limiting their practical applications in commercial food processing and distribution. SERS sensing technology offers high sensitivity capabilities that overcome these constraints.

Antimicrobial properties extend food shelf life

The curcumin-thermoplastic polyurethane (TPU) electrospun wrapper demonstrates significant antimicrobial efficacy, achieving 99.99% reduction against Staphymus aureus and 99.9% against Escherichia coli. This dual functionality – combining sensing with active preservation – represents a significant advance in intelligent packaging systems.

The wrapper exhibits exceptional mechanical properties, withstanding elongation of 716% and maximum stress of 52.3 MPa. This stretchability and conformability enables the material to maintain contact with food surfaces of varying geometries, ensuring consistent sensor performance across different food types.

Spoilage tracking through bacterial emission markers

NSSAW tracks spoilage progression by monitoring dimethyl disulphide, a bacterial emission marker that correlates with food freshness. “In cold-chain logistics and storage, the wrapper can help distributors decide when to ship and sell food by continuously tracking freshness and spoilage chemistry,” says Prof. Ha.

The research team fabricated the wrapper using nanoimprint lithography, e-beam slanted deposition, and electrospinning with nanotransfer printing. This manufacturing approach indicates potential scalability for commercial packaging applications.

Applications across the food supply chain

Prof. Ha outlined multiple applications: “In retail smart packaging, its stretchable, conformal, and biocompatible nature enables non-destructive, on-package checks of quality and nutrition markers – without any damage to food – supporting point-of-sale quality automation and transparent date labelling. Thus, the real-world uses of our technology span the entire farm-to-fork chain.”

For high-value products, the system enables quantitative tracking of purines such as hypoxanthine, supporting premium-grade verification and shelf-life determinations. “NSSAW can act as an on-food freshness indicator during consumer storage for home use and meal-kit delivery, linking chemical changes to easy-to-interpret signals over time,” Prof. Ha explains.

Industry implications for food manufacturers

The technology presents significant implications for food manufacturers and retailers currently reliant on conservative date labelling and periodic sampling. Real-time quality verification could enable dynamic pricing strategies based on actual freshness rather than elapsed time since packaging.

Prof. Ha notes: “As active packaging, the curcumin-TPU, with its antimicrobial properties, complements sensing with preservation to extend shelf life in distribution and retail.”

The research suggests that within 5–10 years, packaging systems that both preserve food and continuously verify quality could transition from pilot programmes to mainstream adoption. Such systems could reduce food waste, improve safety protocols, and enable more precise recall procedures based on chemical markers rather than batch numbers alone.

The research was conducted in collaboration with Professor Junseong Ahn’s group, Professor Sunae So’s group at Korea University, and Principal Researcher Jun-Ho Jeong’s group at the Korea Institute of Machinery and Materials.

Reference

Ha, J.-H., et al. (2025). SERS sensor integrated in stretchable and antimicrobial wrapper for food quality monitoring and preservation. Small, 21(38). https://doi.org/10.1002/smll.202501808