Recycling: Filtrox shredder configured to reduce volume of layered filter residues by more than 90 percent

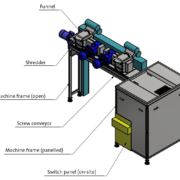

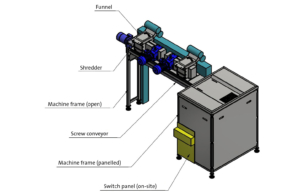

Filtrox AG has redesigned their recycling shredder to make it more efficient and to fit into confined spaces.

Filtrox, a globally operating company based in the Swiss town of St. Gallen, develops and produces layered filters of various shapes and sizes for use in food production as well as in the chemical and pharmaceutical industries. Offcuts produced during the cutting process were previously shredded using two machines and then transported away via chutes to either side of the shredding plants, both of which had two containers for this purpose. However, this solution required an enormous amount of space, which considerably impeded the work processes.

The company therefore sought an alternative option and found what it was looking for at Erdwich Zerkleinerungs-Systeme GmbH: The company from Igling in Bavaria adapted a model for cardboard shredding to the confined conditions on site in such a way that the two newly installed plants require less space overall and the volume of filter material residues is now reduced by more than 90 per cent. In this way, emptying of the directly connected collection container is also less frequent.

Filter layers perform complex tasks in the chemical, food and life science industries by removing a wide variety of particles from liquids, depending on the purpose for which they are used. For example, they ensure that the cork taste disappears from wine and turbidity from beer and are used to purify extracts or fermentation broths that are subsequently processed in the flavouring industry or for pharmaceutical purposes.

“To achieve this effect, the filter layers used for depth filtration consist of a cellulose or polymer fibre matrix,” explains Dennis Haag, Head of Engineering and Maintenance, at Filtrox. “The matrix is enriched with mineral filter aids and bonded together via a resin binder.”

Modification for confined spaces

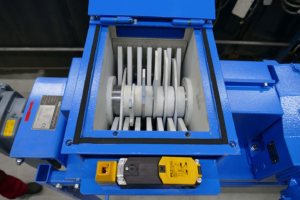

Although the material thickness of the filter layers is only between 3.2 and 4.6 mm on average, the efficient shredding of the materials is a challenge. “Since the filter layers consist of a very dense, fibrous material, it is essential to take this into account when designing the plant,” reports Harald Erdwich, Managing Director of Erdwich Zerkleinerungs-Systeme. “Otherwise, the filter layers may not be drawn in properly by the knives with the result that the machine may consequently work inefficiently.” Another problem was the lack of space in Filtrox’s production hall. The new plants, which were to replace the two machines previously used, therefore required a particularly compact design so that the work processes would be inhibited as little as possible. This applies, for example, to the collection containers, which have to be removed regularly and replaced by empty containers.

After material tests in their in-house Technical Centre and evaluation of the space conditions, the Erdwich experts decided to modify the FKZ fine cardboard shredder for use at Filtrox. While the previous FKZ1300 and FKZ1600 models are relatively large with cutting unit sizes of 1,278 and 1,616 mm respectively, a much smaller version had to be developed for filter layer shredding. Due to the limited space available, the two FKZ200s used at Filtrox have a very small cutting unit with a width of approximately 200 mm and specially adapted hoppers, as well as a low drive power of 2.2 kW each. The filter trimmings, fed directly from the processing machine, have a width of between 10 and 50 mm, depending on the product. Thus, a throughput of about 140 kg/h can be achieved per shredding plant.

Ripper blades improve feed ratio

“Another reason for the high throughput is the knife system,” explains Erdwich. “Ordinary knives are often not able to grip some materials properly, so that manual help, for example with a manual feed press, is required. This problem does not occur with the ripper blades, because they have a better grip on the material and thus achieve a more efficient feed behaviour.”

The integrated comb ensures that the material does not wrap around the cutting rotor and can be shredded without problems. In the subsequent shredding process, the filter layers are not so much cut as torn apart, which happens regardless of the material: The blade insertion sequence does not have to be adapted for different types of filter layer, but works equally well for all types.

After the material has been shredded to a size of about 20 x 50 mm, it is transported by a screw conveyor with a drive power of 1.1 kW into a collecting container with a capacity of about 1000 litres. The entire shredding and collection process takes place in a very confined space. The compact design not only facilitates exchanging the containers, but also makes the machine very easy to maintain, for example, by allowing easy cleaning of the built-in sieve.

Volume reduction of up to 97 percent

Filtrox now also saves space through the shredding process itself. This is because it was possible to reduce the volume of the filter layers by approximately 97 percent by commissioning the new plants. This means that the collection container has to be emptied less often, saving valuable working time. The shredded material is then processed further.

- For more information, visit: filtrox.com and www.erdwich.com